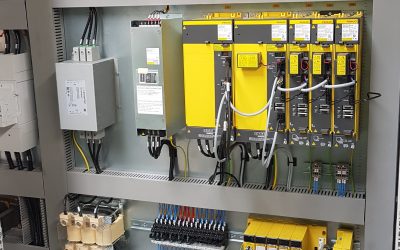

Elb 3 mtr surface grinding machine

Control panel upgrade. The original NC system was replaced with a Fanuc Oi-D CNC control system coupled with Alpha iSV servo drives for the main axis and a Control techniques Mentor SP DC drive for the 315A DC spindle motor. Soag developed the software for the PLC,...

Furnace Door (No.3)

Replacement panel designed around the original concept. Simple pushbutton control system, Pilz safety monitoring relay and ABB inverter for variable speed control of the furnace door raise and lower. Soag designed and built a more compact...

Bryant Ex-Cell-O

Conversion of a dual cabinet system into one modern control panel. For this project Soag designed and built a control panel to replace the two original panels controlling a Bryant Ex-Cell-O grinding machine. Control cabinet - Before and After Using a Siemens 840D cnc...

Charger control panel

A replacement control panel designed around the original concept. With the addition of semi-automatic positioning at each furnace, quench tank or loading table. To assist in the positioning of the charger a Laser measuring device was utilised along with a Siemens...

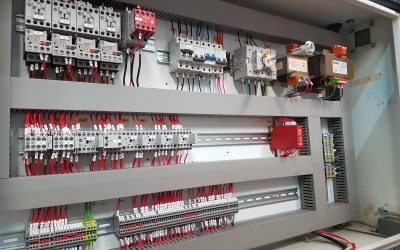

Furnace door control cabinet

Replacement of existing door control panel with modern control gear. The original control panel was becoming troublesome and required updating, using the original wiring diagrams Soag designed a more compact control cabinet. The new panel included a Inverter to...

Pallet inverter machine

For this project the pallet inverting machine was fitted with new safety access guards allowing entry from one single point of access. To prevent operation of the machine or inhibit the cycle, safety light curtain access was required. Upon entry, breaking the light...

Springfield – Rotary grinder

Replacement of existing electrical control gear panel, with new modern equivalent control gear. For this project, no electrical wiring diagrams/schematics were available for the machine. Each wire had to be manually traced and identified and new electrical wiring...

Herbert No.4 Lathe – Replacement control panel

Soag were approached by an end customer to provide an upgrade to an electrical control panel for a Herbert No4 lathe. The original control panel, designed in the late 50’s, was becoming troublesome and dangerous. Also the customer was concerned that the panel did not...

Portable Line Boring machine

Soag were asked to design and build a control system to operate a portable boring machine, this consisted of 2 linear servo axis and a rotary spindle. The control cabinet needed to be portable with quick disconnect cables feeding the servo axis motors. Siemens...

Portable gantry milling machine

For this project Soag were asked to design and build a control system to operate a portable gantry milling machine this consisted of 3 linear servo axis and a rotary spindle. The control system had to be designed to comply with UL508A. New electrical drawings/wiring...